To truly understand the nuanced differences between analog and digital connectivity, it helps to first understand…plumbing? Well, yes – as it turns out, some basic plumbing mechanics are analogous to connectivity in the A/V space. Intrigued? Read on and our Chief Technology Officer Kevin Zheng breaks it down for you.

Digital Communication – High-Tech Plumbing

Digital communication dates all the way back to telegraphy, in which complicated messages can be encoded with two distinctive signals (dots and dashes), also known as Morse code. It addressed the challenge of transmitting messages reliably over long distances. Today, the challenges remain the same in digital communication, just with a different name and on different scales.

The digital revolution took off with the invention of transistors and integrated circuits. Instead of using dots and dashes, communication systems now use 0’s and 1’s, or bits, often represented by distinct electrical signal levels (e.g. a low voltage means “0”, and a high voltage means “1”).

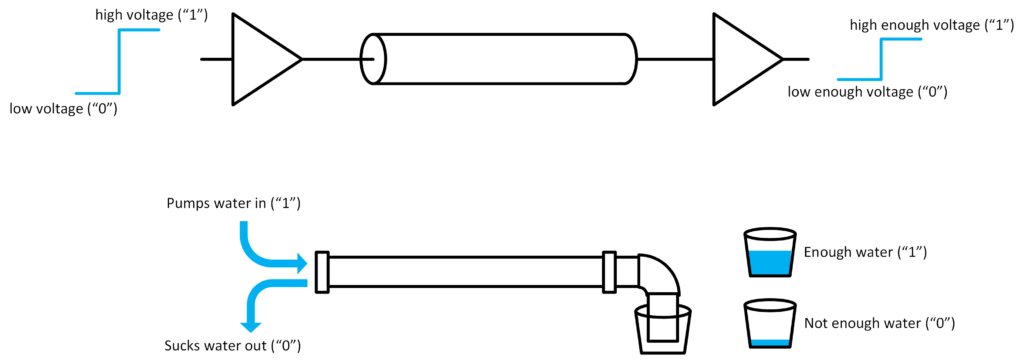

Copper is typically used as the transmission medium, forming a physical connection between a transmitter and a receiver. If I were to explain a digital communication link to my grandma, I would use the analogy of a water plumbing system like you see below.

A transmitter acts as a “water pump” that can either pump water into or suck water out of the pipe. The receiver on the other end will decide if water has been pumped or drawn by observing the water level (measured voltage). Despite the simplicity of this picture, it shows the potential challenges in the system.

If you wait long enough, the water in the cup will either rise or drop to sufficient height so a confident decision can be made. This is analogous to a low-data-rate transmission. As the frequency of water pump/suction increases (higher data rate), the amount of water flowing to the right side will decrease, which is a concept called “loss” in data communication.

One of the biggest limitations in this scenario is the water pipe itself, just like a copper wire. Let’s discuss in more details why it’s increasingly more difficult to transmit reliably on copper over long distances.

Limitations of Copper

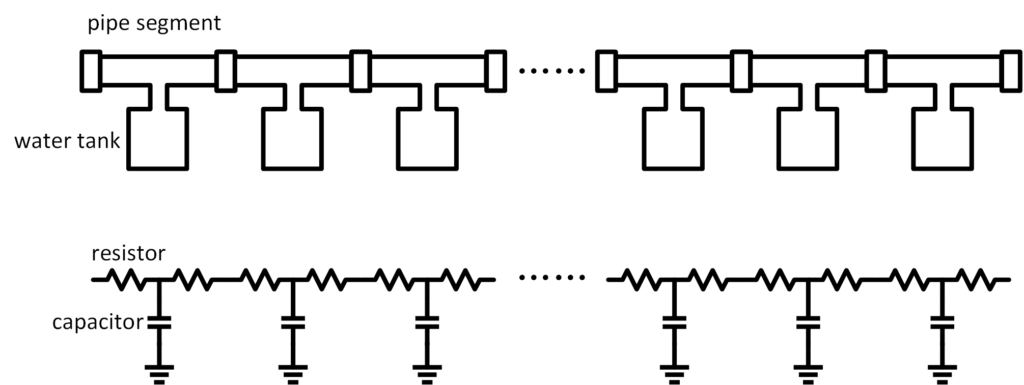

To continue the analogy above, a realistic copper cable in plumbing terms would look more like the following. It consists of many pipe segments, each attached to a small water tank. The diameter of the pipe defines how fast the water can flow – in the world of connectivity, this is known as resistance. A narrower pipe means higher resistance. The water tank is similar to a capacitor, which requires some time to fill and empty proportional to its size.

Intuitively, it becomes obvious what could limit the speed at which water flows from one end to the other – a narrower pipe and bigger tanks. As water enters each pipe segment, a portion keeps going to the next segment and the rest fills up the tank. After several segments, less and less water can exit on the right (the concept of signal “loss”) unless we wait long enough for all the tanks to be filled. Longer pipes would lead to higher loss of water on the water side, and a longer wait is required. Although this might be an over-simplified model (a more detailed analogy can be found here, it’s powerful enough for us to understand the fundamental challenges in communication over copper.

Now let’s bring the focus back to copper cables: Just like water pipes, longer copper cables pose significant challenges when used in high-speed data links. Its higher resistance and accompanying capacitance limit the data rate. What about using thicker cables like using wider pipes to lower the resistance? Unfortunately, nature isn’t that kind to us. In addition to the problem of the cable being bulky and heavy, thicker cables tend to come with higher capacitance. There is also an electromagnetic phenomenon called skin effect, which ultimately limits the effectiveness of thicker cables at high frequencies. What’s worse, there is also the issue of electromagnetic interference (EMI), which can cause crosstalk noise in a multi-lane communication channel. Despite the abundance and nice properties of copper, we are quickly approaching its physical limits in many high-speed applications.

Fiber Optics to the Rescue

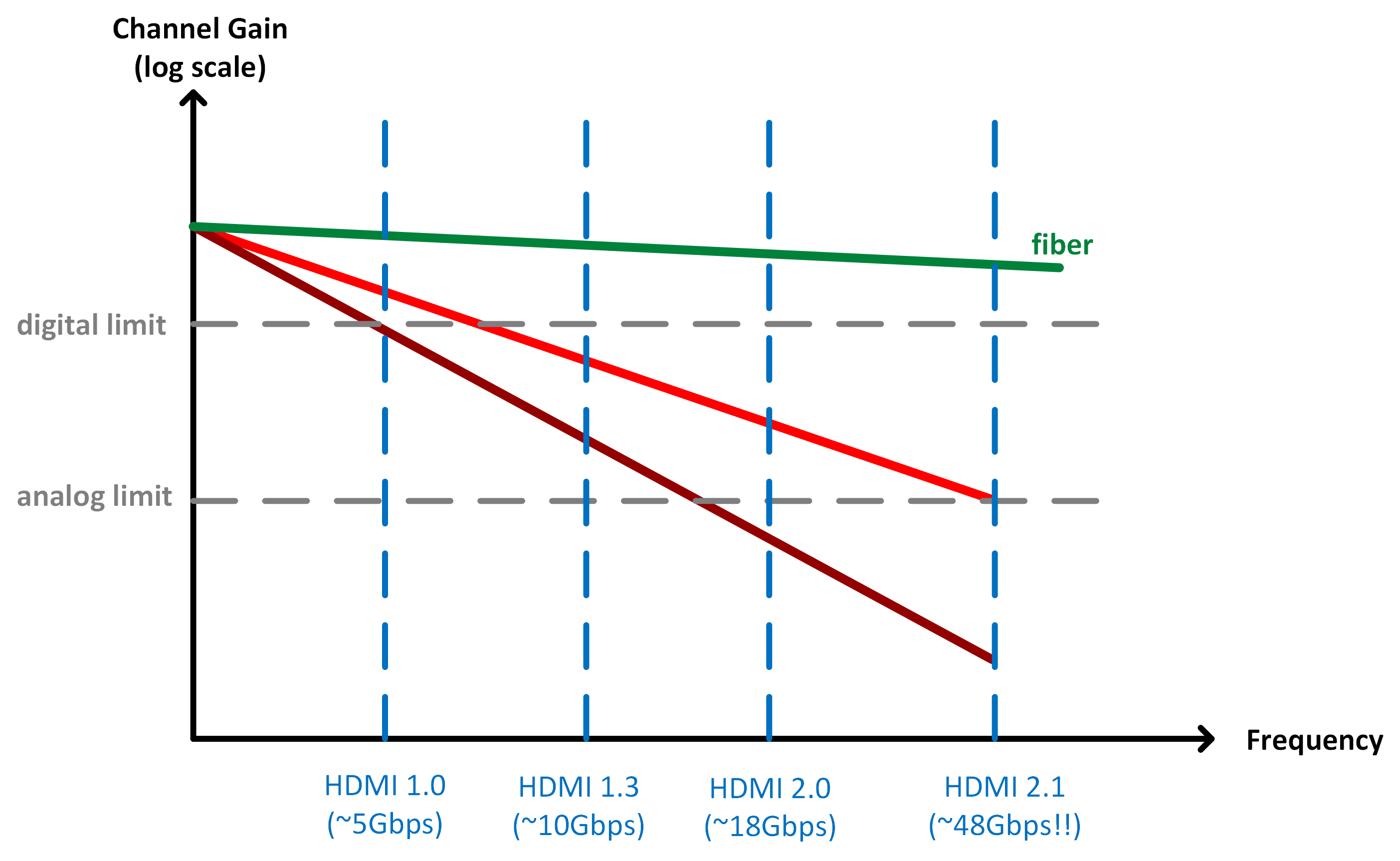

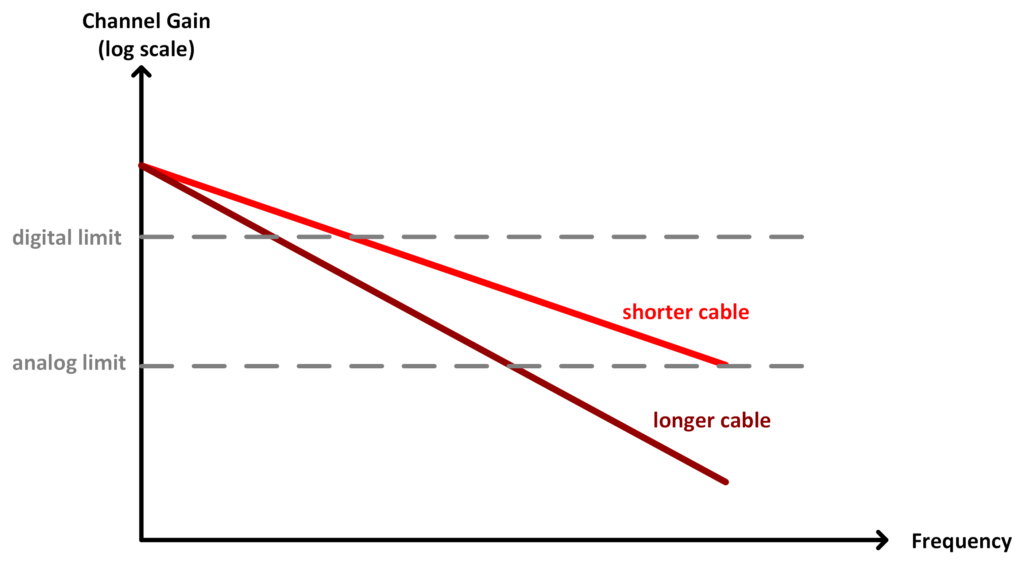

The illustration below graphically depicts signal gain traveling through copper cables in the frequency domain.

The signal loss is smaller for lower frequency (i.e. wait longer). Longer cables will have higher loss than shorter cables within reasonable dimensions. On the graph there are also two dashed lines indicating a digital and analog limit. When the signal gain is still above the digital limit, the received bits can be decided with high confidence.

However, we can only operate in this region up to a limited frequency before we enter the analog regime. The signal loss here is high enough that there is no clear “black and white” answer for the received bits. Analog signal processing techniques and circuits (equalizers) need to be built to recover the signal reliably. This leads to more power consumption, yet it still delivers undesirable performance in many cases.

Then there is the harder analog limit, illustrated below, in which the signal could be considered non-recoverable in the presence of nonidealities in circuits, product manufacturing and operating environments. This will limit the length of the copper wire that could be used. Note that the scale is all relative – a shorter cable today could be considered a long cable tomorrow when speed goes up.

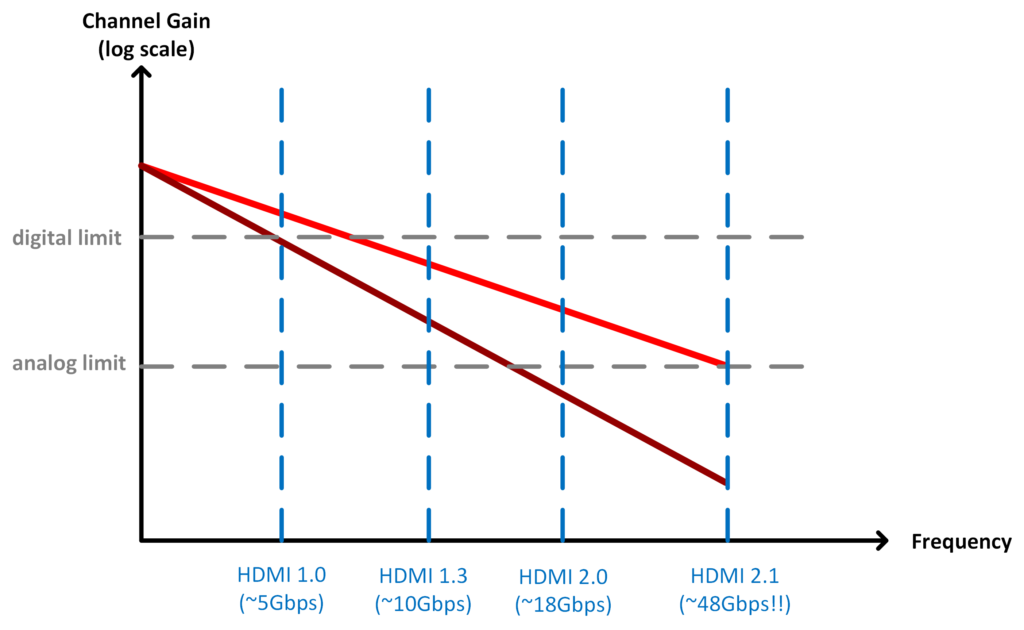

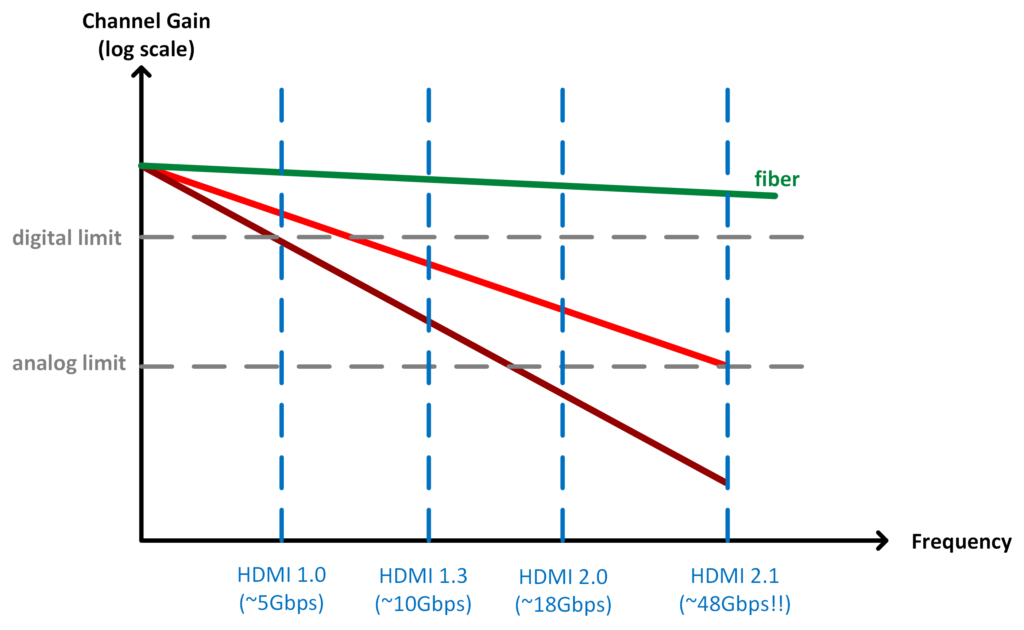

While this is a common problem for all communication protocols, we will use HDMI as an example here. This is how the specified data rates would line up in the graph:

Each generation roughly doubles the data rate (the latest jump from HDMI 2.0 to 2.1 sees a 2.7x increase!), and we will (if we haven’t already) hit the copper limit. Extrapolating to HDMI 3.0, it’s obvious that we need technologies and products that can replace copper wires. This is where fiber optic technology really shines. After all, the ultimate physical limit is the speed of light.

The major advantages of using fiber as the copper replacements are the following:

- Speed: fiber channels can have much lower loss than copper. Thus data speed on a fiber cable can be much higher than on copper cables of the same length.

- Distance: fiber channels can allow significantly longer reach. Case in point, the transatlantic Internet cable is fiber.

- Reliability: there are no EMI concerns in fiber cables because light is contained within the waveguide and no EMI waves can exist or enter to cause interruption on data transmissions.

- Durability: don’t let the glass fool you. The high-tensile strength in fiber glass makes it the more durable option than copper. Copper is also more prone to oxidation and corrosion over time.

- Future proof: while the consensus now might be copper is lower in cost, the continuous advancements in fiber optics mean it’s a more of a future-proof technology and could be a more cost-effective solution for all applications in the near future.

The Pure Fi Advantage

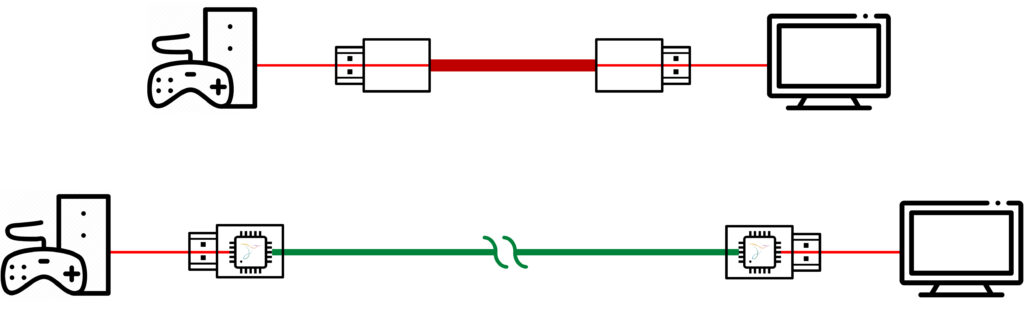

Fiber optics is finding its way to penetrate into our homes. Before we might realize, the simple task of connecting a state-of-the art gaming console to a TV is already causing troubles. An Active Optical Cable (AOC) could be the perfect solution for the ever increasing demand of higher quality content consumption.

Unlike most other cable providers, Pure Fi designs, engineers and builds everything in-house, giving the company full control of the entire manufacturing and distribution process. This “chip to ship” approach is unique in the industry, and sets Pure Fi apart from cable manufacturers that choose to outsource key elements of product development and manufacturing. While this practice may pad margins and net those manufacturers greater profitability, it does so by risking build integrity and increasing the chance of customers receiving a sub-par final product.

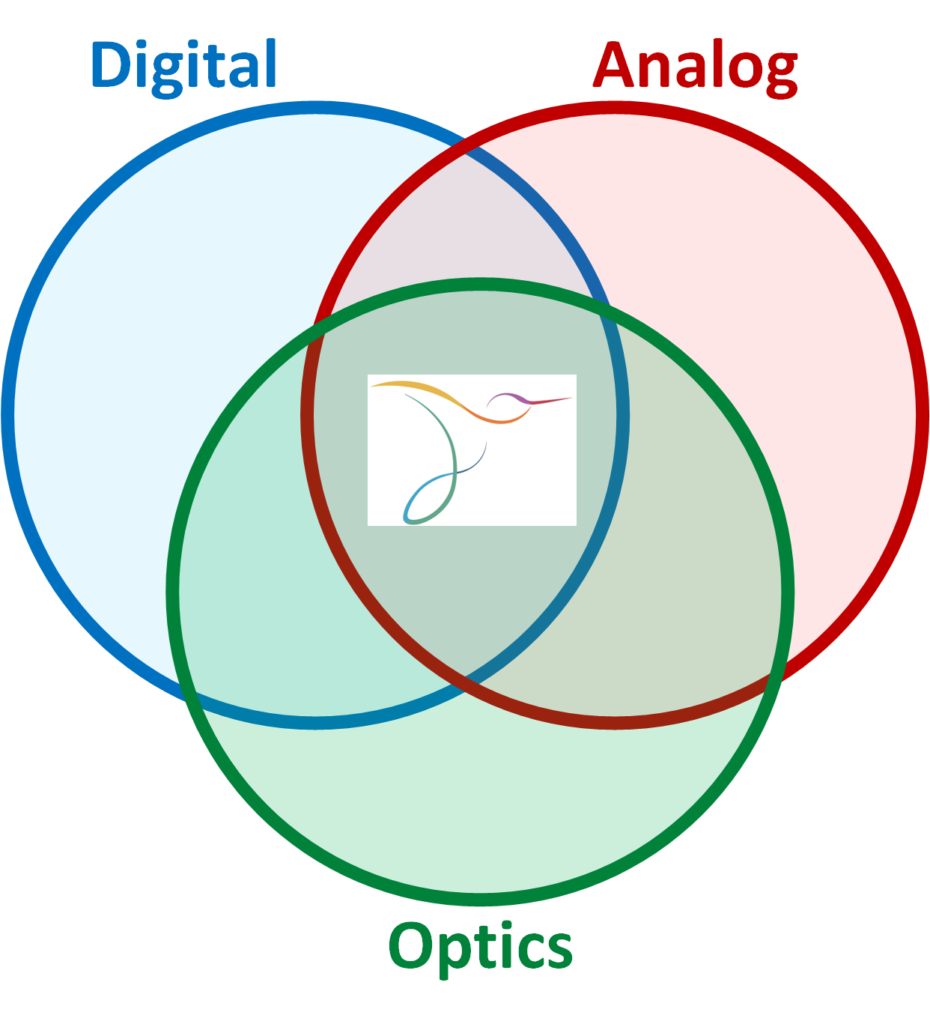

Pure Fi’s team fully understands all aspects of digital, analog and optical signal processing. It is the expertise and experience in the intersection of this signaling trinity that allows us to create a high-speed, lightweight and reliable cable.

Our goal isn’t to simply deliver a solution that will serve our customers well today – instead we’re focused on building optical connectivity solutions that meet (and in many cases, surpass) the latest industry specs to ensure the Pure Fi products our customers purchase today will serve them well for years to come as their connectivity needs evolve.